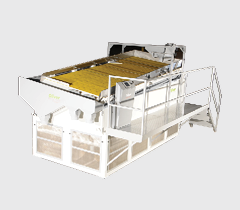

Seed Cleaning and Processing

PMR Grain Systems supply a vast range of precision seed-cleaning equipment and solutions to clean, treat and process seeds and cereals. Our range includes some of the world’s leading brands for seed cleaning from air screen cleaners to gravity separators.

Select the product line below for key features and specification brochures.

Seed Cleaning and Processing Products

Cleaning and Treating

(Cimbria)

Gravity Tables

(Oliver)

Q-Sage

Conveying and Handling

(Perry of Oakley)

Silos and Storage

Complete Plants

Plant Maintenance

and Repairs

We’re always available to meet with you and discuss your Seed Cleaning and Processing requirements, get in touch to find a solution together.

Draminski

Q-Sage

Agco

GSI

Oliver

Harvest

Cimbra

Welvent

Wakely

Skiold

Colderado Mill Equipment

Perry of Oakley

R&R Machine Works

Primary Industries