Seed Cleaning / Silos and Storage

GSI Silos

Efficiently designed to handle maximum loads for unmatched strength. All GSI bins are constructed using the highest-strength steel available.

Series Grain Bins

Maximise your profitability. No matter how high yields are, grain prices at harvest are no guarantee. Growers managing uncertain weather and market volatility can depend on GSI for onsite grain storage that can grow and expand as needed.

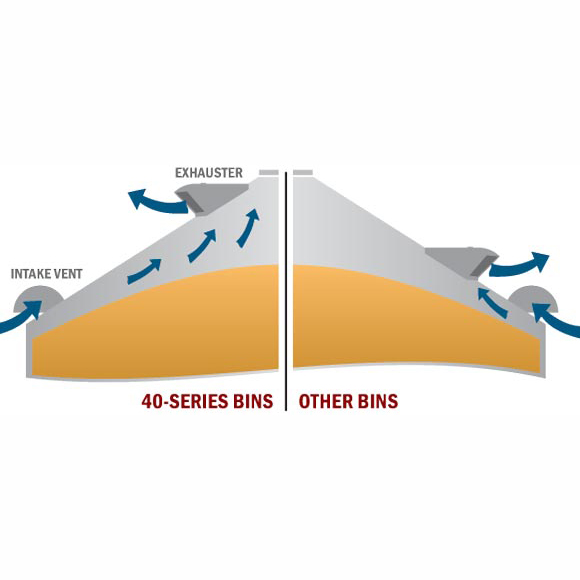

The precision-engineered Z-Tek™ Roof System designed for increased load capacity and larger fill equipment. All floor parts are galvanized for lasting durability and feature a unique locking system that reduces floor movement and supports extreme load conditions.

- Capacities up to 1.9 million bushels

- Diameters up to 156'

- JS500 bolts paired with sealing washers to protect grain

- High-tensile steel sidewall sheets rated up to 70,000 psi (450 MPa) minimum

Evo 50 Grain Bins

Take control with better protection through smarter design.

Engineered from the small details on out, EVO 50 defends your grain from the elements. We’ve maximized strength at each connection and used an advanced sealing system to ensure the outside stays out and profit potential is secured inside. If you’re looking for storage as dedicated to your livelihood as you are, this is it.

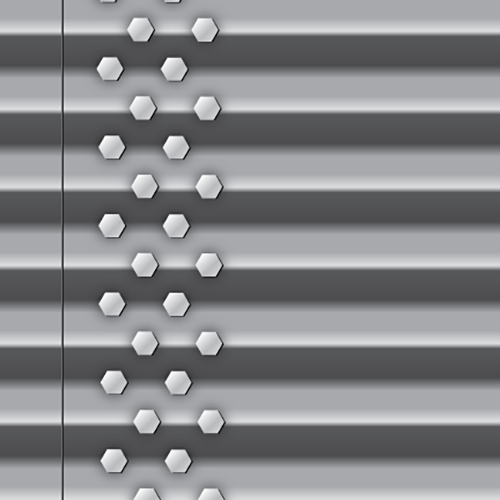

- Optimized bolt pattern

- Interlaced laminated sheets

- Hardware with 4x corrosion protection and a water-tight seal

Double-length sheets (on 90’+ dia)

You’ve weathered the storms of farming and earned a great harvest. GSI helps you to protect it. It’s all about putting you in control and powering your profit. Protecting your Inventory since 1972. GSI supports agriculture around the globe with the most extensive global manufacturing footprint and dealer network in our industry. We bring our customers local solutions with global expertise.

Let’s Talk

PMR can assist you with on-site silo base construction. We’ll handle everything from excavation to concrete laying.

Give our sales team a call today and let us find a solution together.