Seed Cleaning / Cimbria

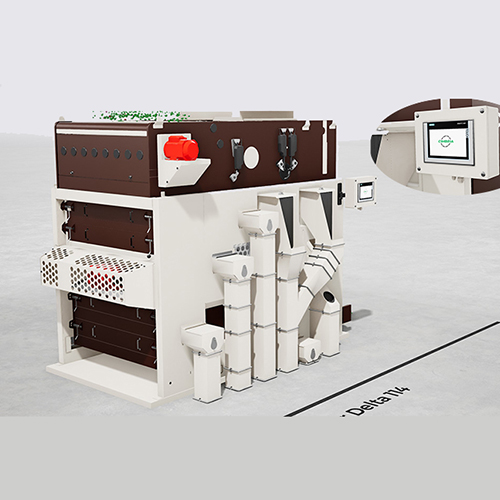

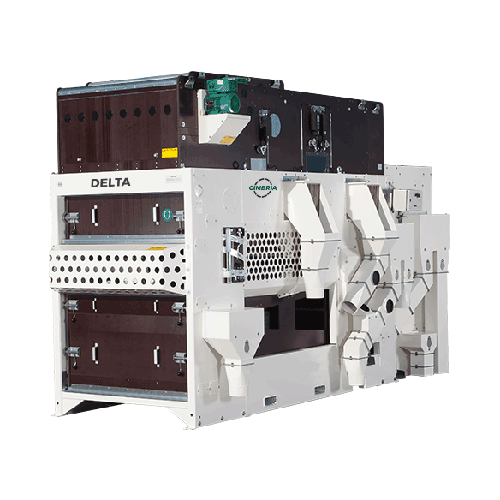

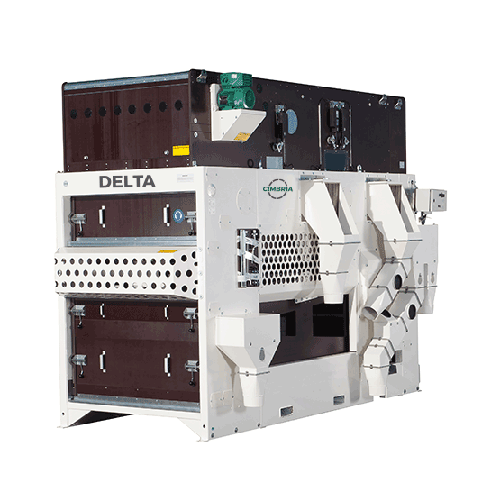

Air Screen Cleaner

Delta Air Screen Cleaner for optimum flexibility and efficiency.

Cimbria has a complete lineup of precise cleaners to remove impurities. The gentle cleaning process helps maintain seed quality and germination potential by minimizing damaged seeds.

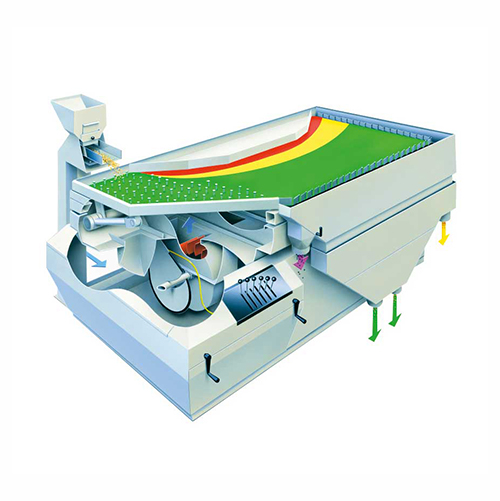

Gravity Tables

Effective separation of Kernels and Granular Products.

Gravity Tables are used for the separation of any kind of kernel and granular product of almost identical size but with different weights.

Utilised when the limits of air-aspiration systems and screening are reached.

Gravity separators are an additional piece of equipment for separating more accurately according to specific weight.

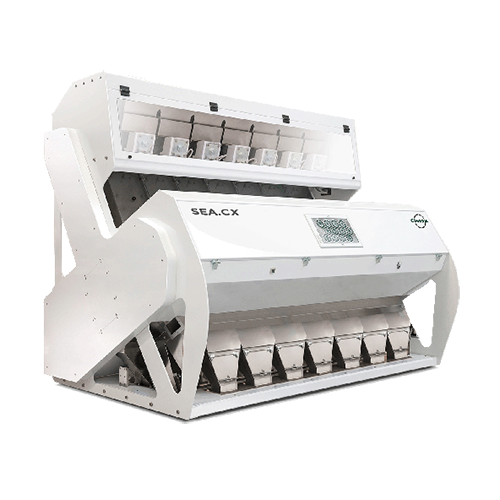

Optical Sorting

Advanced full-color and infrared sorting solutions, designed to handle even the most complex sorting applications.

Optical sorting uses the most advanced technology to sort micro-sized foreign bodies and defects which cannot be distinguished by the human eye. The different sets of cameras applied in the Cimbria range of optical sorters are conceived to accomplish various kinds of sorting, with extreme accuracy and speed.

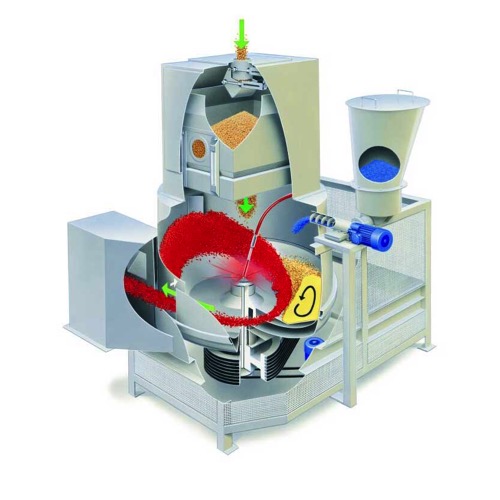

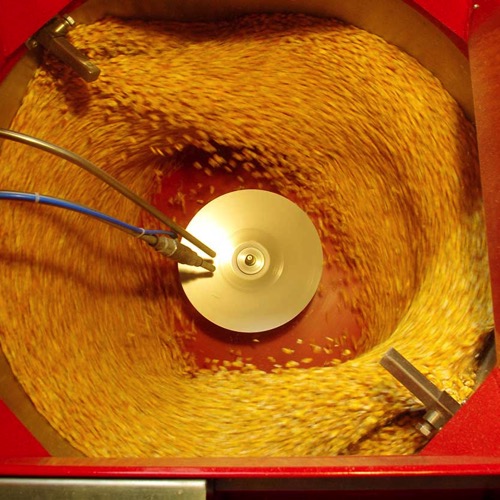

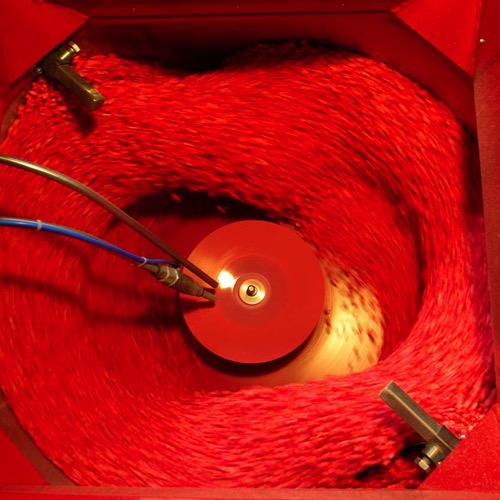

Seed Coating & Treating

Modern coating technology for increased seed growth ability.

Prior to being sown, the seeds have to be protected against attack by fungi and pests.

Cimbria seed treaters are suitable for all types of liquid or powder treatment. Multiple contact of each seed surface with the atomized treating agent in the mixing drum ensures exact and uniform coating of the seed surface. A closed vacuum system ensures zero pollution with no aerosol leakage.

Since 1947 Cimbria has been one of the world’s leading companies within industrial processing, handling and storage of grain and seed, as well as animal feed, foodstuffs and other bulk products.

Let’s Talk

PMR can assist you with everything from cleaning & treating products,

gravity tables, debearders and screen cleaners, conveying & handling, silos &storage to complete plant design.

Give our sales team a call today and let us find a solution together.